Aeronautical Grade Adhesive

Technical Data

Key Benefits

-

Pressure-sensitive aeronautical grade adhesive for quick application with immediate handling strength to speed assembly.

-

Strength to replace liquid adhesives and mechanical fasteners in many applications.

-

Neat application without the mess, ooze, and curing delay of liquid adhesives.

-

It can typically tolerate differential movement in the shear plane up to 3 times in thickness.

-

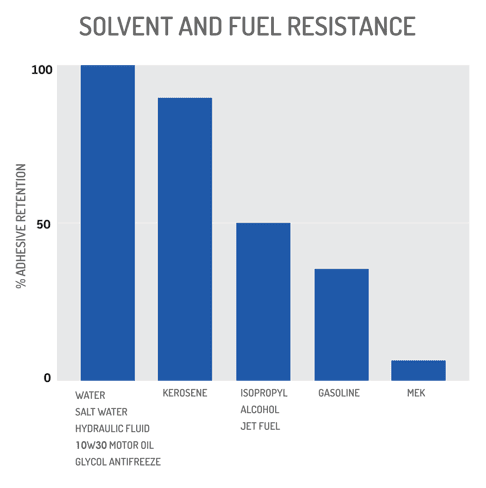

Bonds and seals simultaneously with durability to withstand vibration, impact, and weathering.

-

Provides a clean, smooth appearance

- Prior Cleaning

All substrates are best prepared by first using the enclosed Isopropyl Alcohol bonding agent wipes thoroughly (included with product) prior to applying the Aeronautical Grade Adhesive to the module frame. - Pressure

Bond Strength is dependent upon the amount of adhesive-to-surface contact developed. Firm application pressure (min. 15lbs PSI) develops better adhesive contact and helps improve bond strength. - Humidity

The suggested humidity for the application is below 90%. SolaTrim adhesive should be kept and applied below 79% R.H.

- Temperature

Ideal application temperature range is 20°C to 50°C (68°F to 122°F). Minimum suggested application temperatures to 10°C (50°F). To obtain good performance, surfaces should be dry and free of condensed moisture.

- Time

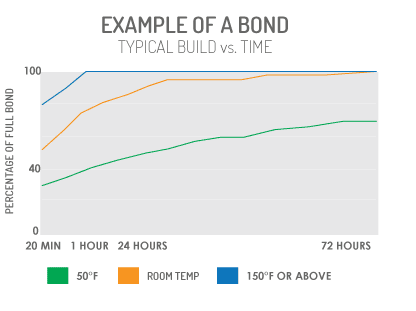

After application, the bond strength will increase as the adhesive flows onto the surface. This flow is faster at higher temperatures and slower at lower temperatures.

Note: This technical information and data should be considered representative or typical only and should not be used for specification purposes